Bristol Automated Synthesis Facility

Our Automated Workstation (Chemspeed Technologies) is available for automated parallel chemical synthesis, with capabilities including inert atmosphere, solids dispensing, temperature control from −70 °C to 120 °C, high pressure (up to 80 bar) and integrated solid-phase extraction with dedicated LC-MS off-line analysis.

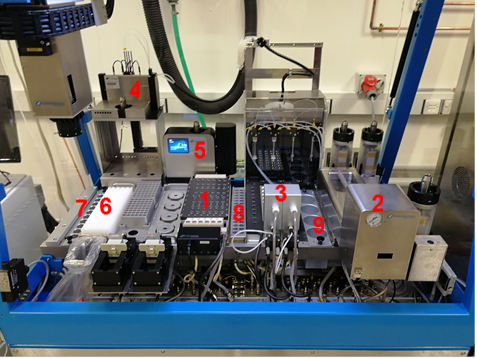

The School of Chemistry at Bristol University hosts the EPSRC-funded SWING Automated Workstation manufactured by Chemspeed Technologies.

The self-contained SWING platform and reaction vessels can be inertized in order to handle moisture- and air-sensitive reagents and intermediates (<10 ppm O2 and H2O). Our set-up can automate and analyse most types of reactions that are employed in modern synthesis.

The ISYNTH reaction block allows 48 reactions to be run in parallel in 2 mL or 8 mL disposable glass vials, with agitation speeds of up to 800 rpm. An integrated thermostat enables temperature control between −20 °C to 120 °C and a connected vacuum pump allows for evaporation.

The MTP pressure screening block enables reactions to be conducted at high pressure (up to 80 bar) with reactive gases (e.g. H2, CO) and under thermostat control (−20 °C to 120 °C). Up to 96 reactions can be conducted in parallel using 2 mL disposable glass vials.

Additionally, the workstation also enables 32 reactions to be run in parallel in 13 mL glass array reactors equipped with double jackets for accurate temperature control (−70 °C to 120 °C).

Using SWILE technology, our SWING platform can gravimetrically pick & dispense solids and powders (e.g. catalysts, base, other additives; from 0.1 mg to 20 mg). The 4-needle tool for volumetric aspirating and dispensing of liquids allows the versatile handling of solvents, solutions and liquid reagents (2 x 10 mL syringe and 2 x 1 mL syringe).

For work-up processes the integrated solid-phase extraction rack allows filtration of reaction mixtures through any desired solid phase (e.g. silica, Celite, MgSO4).

The reactions can be sampled at various times and the sample vials loaded onto a dedicated LC-MS for off-line analysis.

Contact Details

Please contact chem-basf@bristol.ac.uk to find out more information

Applications for use

We welcome applications for use to complete this application form Chemspeed Application Form (Office document, 26kB), you can see an example of a completed form by opening Chemspeed Application Form Example (PDF, 180kB)

Examples of Automated Synthesis Application

Optimisation by Automated DOE (PDF, 913kB)